Wire Tensioning Equipment in Waterford, WI

Sarcem America, Inc. specializes in all things involving coil winding and single- and multi-spindle winding machines. We serve customers across the country, with knowledgeable sales reps in each region to assist you with your complete equipment needs. Whether you’re looking for a training partner to help educate your staff or need ALTIC tensioner repair and calibration from experts who know the fundamentals of these machines, we’re ready to serve you.

Winding Machine Service and Repair

Sarcem America provides complete machine repair service on GS Automation, Ducap, ALTIC, Synthesis, and Bobifil and Amacoil equipment. We’re available on a contractual or as-needed basis, to ensure your equipment is safe and operationally reliable. We can complete repairs on-site at your facility in Waterford and Milwaukee, WI or have your equipment serviced at our state-of-the-art facilities.

We also supply spare parts for all major winding equipment brands. We stock most routine parts and essential components, and can order specifically for your equipment if your needs fall outside the realm of our stock.

Prototype Winding Service and Repair

We’re pleased to offer prototype winding service and repairs to our customers. Over the years, we’ve been asked by numerous customers to provide wound prototypes, to assist them in qualifying their new designs. This service allows our customers to keep their machines up and running for production, while we wind prototypes at our facilities. Through this service, customers are able to evaluate new designs and the feasibility of new products before deploying them in practice.

Winding Machine Training

Maintenance and repair are vital to the longevity of your equipment and its total ROI. When it comes to proper upkeep, Sarcem America, Inc. is always willing to teach your maintenance technicians the ins and outs of these machines. We provide on-site training or training at our facility in Waterford, WI. We offer training programs for programming, machine set-up, machine operation and preventive maintenance. We can also customize a training program to meet your specific needs.

ALTIC Tensioner Repair and Calibration

ALTIC is the industry-leading name in coil tensioners. If you own and operate ALTIC equipment, put your trust in our experts for ALTIC tensioner repair and calibration services. We’ll ensure your machines are running efficiently and delivering superior performance—and we can calibrate them over time as their service life begins to take a toll.

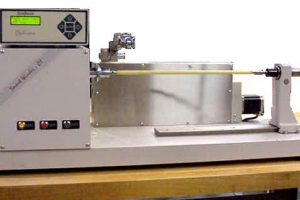

PROPER WIRE TENSIONING EQUIPMENT

How do you ensure consistency in your winding process? In our experience, the most often overlooked detail of coil winding is proper and uniform tensioning. Uniform tension is critical to the production of high-quality products. Every manufacturer of magnet wire publishes a chart of recommended wire tensioning equipment, by wire size, for its products. Typically, you will use a value equal to 50 – 80% of the maximum recommended tension to ensure that the magnet wire is not elongated during the winding process (which would decrease the diameter of the wire and increase its resistance), and possibly damage the wire insulation due to stretch.

A tension meter is used to measure winding tension on the magnet wire. The ideal spot to measure tension is between the final wire guide device (pulley or wire tube) and the coil since this gives the true tension on the magnet wire. Tensioners can be mechanical, with either direct reading for round coils, or dampened for square or rectangular coils, or electronic, which can be programmed for sampling rate. Another often-overlooked element of tensioning is whether your tensioner compensates the applied tension during the wire build of your coil.

As your coil builds in size, you will be pulling more wire length per second of winding. If your tensioner does not compensate for this, your tension will increase as your coil builds. To ensure uniformity and consistency, make sure that your tensioners, either mechanical or electronic, are of the compensating type. We feature tensioning equipment manufactured by ALTIC and SYNTHESIS.

Current Winding Machines

Our website depicts our latest product listing of our winding equipment. Please contact us for more details of any specific machine that may be of interest to you. Our machines can be configured to meet your winding needs. We are a full-service distributor of Winding Machines, Tooling, Accessories and Services. When you have a project that you need assistance with, we will do everything possible to help you find the winding solution that meets your winding expectations. If we don’t have a machine or service for your application, we will help you find someone who does.

Trust the Equipment Experts

Sarcem America, Inc. is the national authority on multi- and single-spindle winding machines and repair, as well as prototyping and training. Put your equipment into the hands of a trusted expert and contact us today at (920) 868-3266 to learn more about our services.